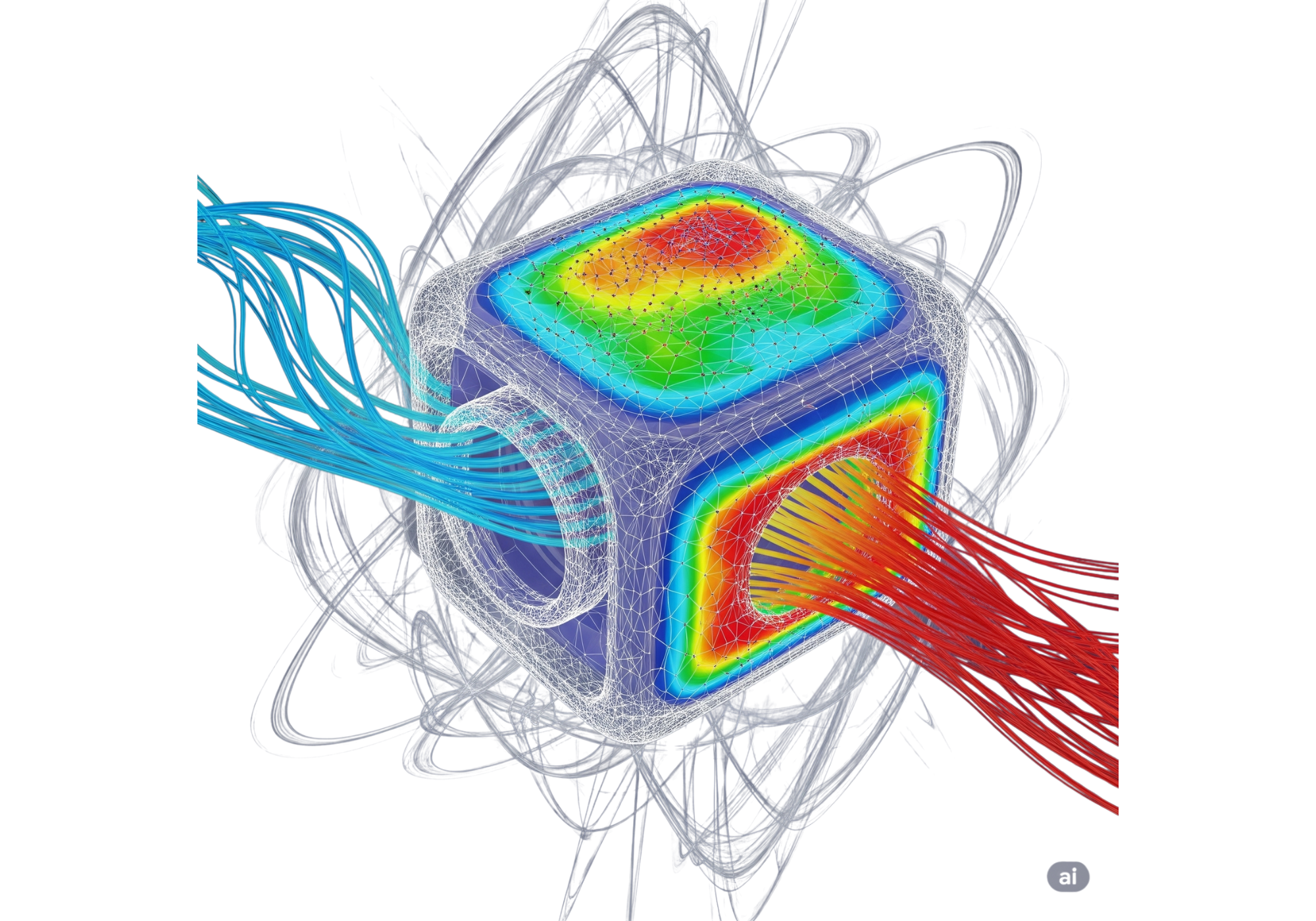

FEA allows engineers to evaluate the structural strength, durability, and safety of a design under different loads and stresses. By digitally testing materials and geometries, manufacturers can reduce costly...

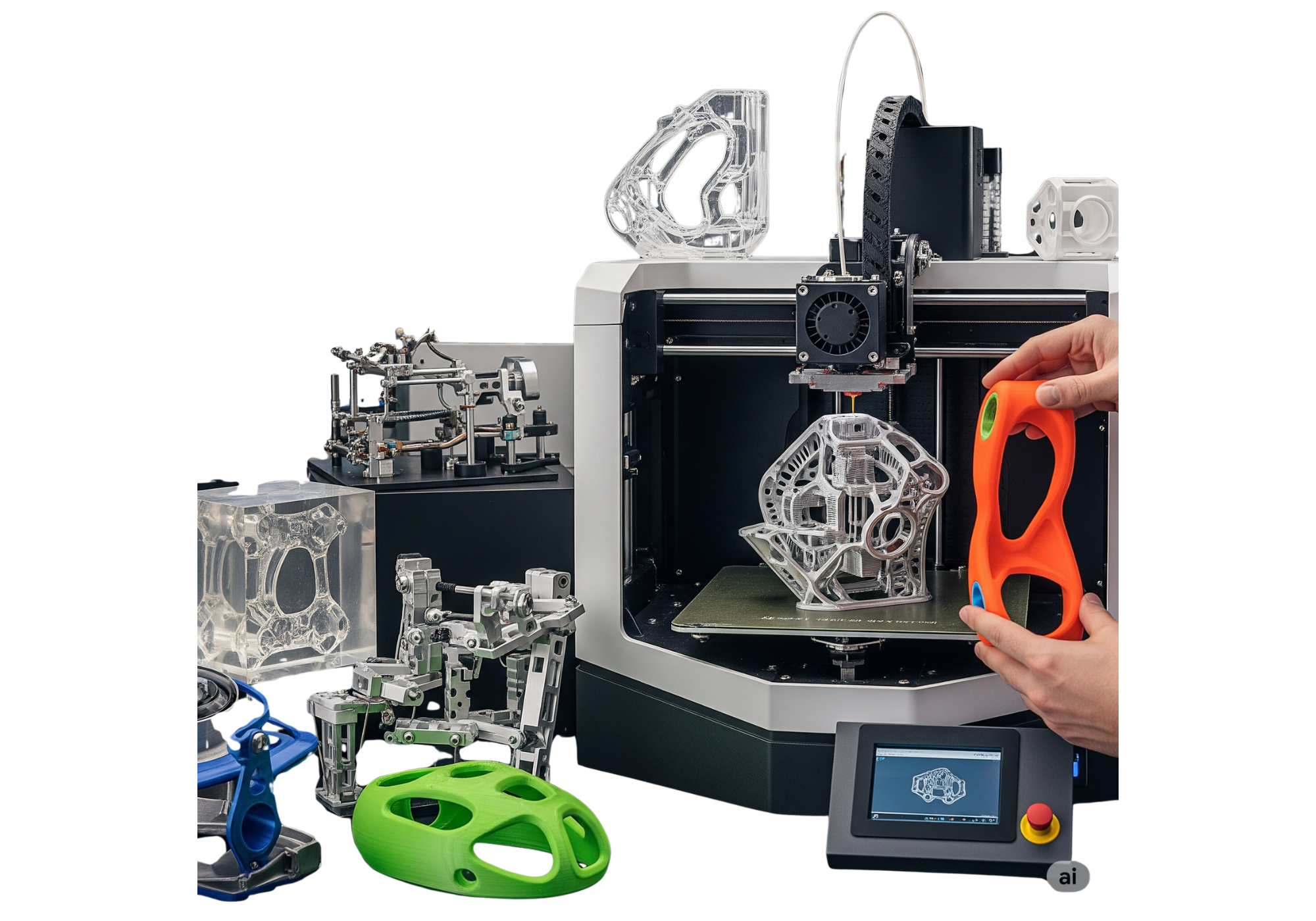

Additive manufacturing, or 3D printing, has revolutionized prototyping and small-batch production. Engineers can now produce complex geometries, test designs rapidly, and validate functionality in a matter of hours....

Turning an idea into a market-ready product requires a structured process that blends creativity, research, and engineering discipline. Product development services encompass: Research-driven engineering ensures innovation is backed...

Not every company has the in-house expertise or resources to handle complex engineering challenges. This is where consultancy and mechanical design services step in. Expert consultants provide guidance...

The final step of the innovation chain is manufacturing. With digital tools feeding directly into CNC machining, injection molding, or 3D printing, the transition from prototype to production...

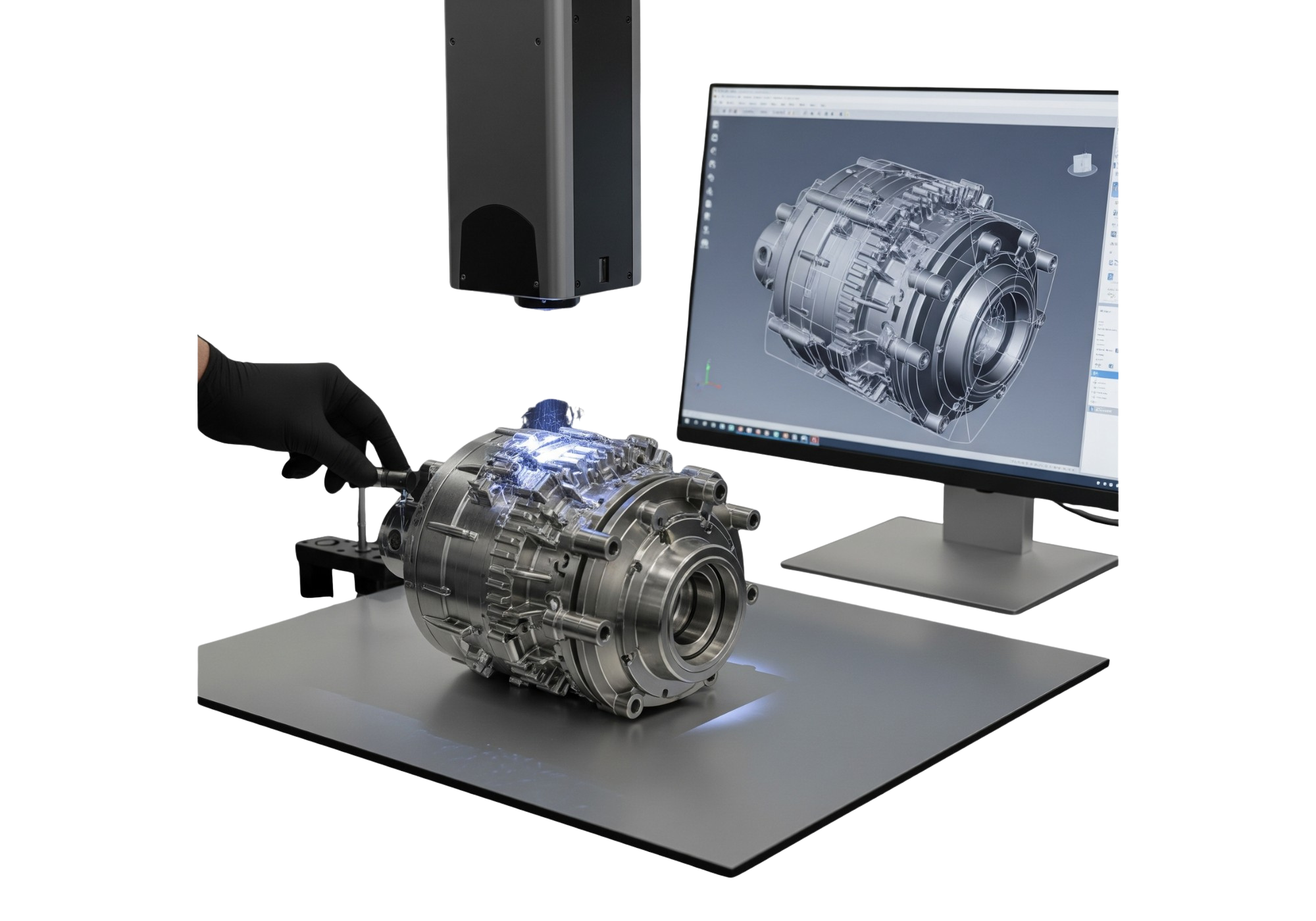

In many industries, reverse engineering plays a vital role. Whether analyzing competitor products, digitizing legacy components, or creating CAD models of worn-out parts, reverse engineering helps businesses save...

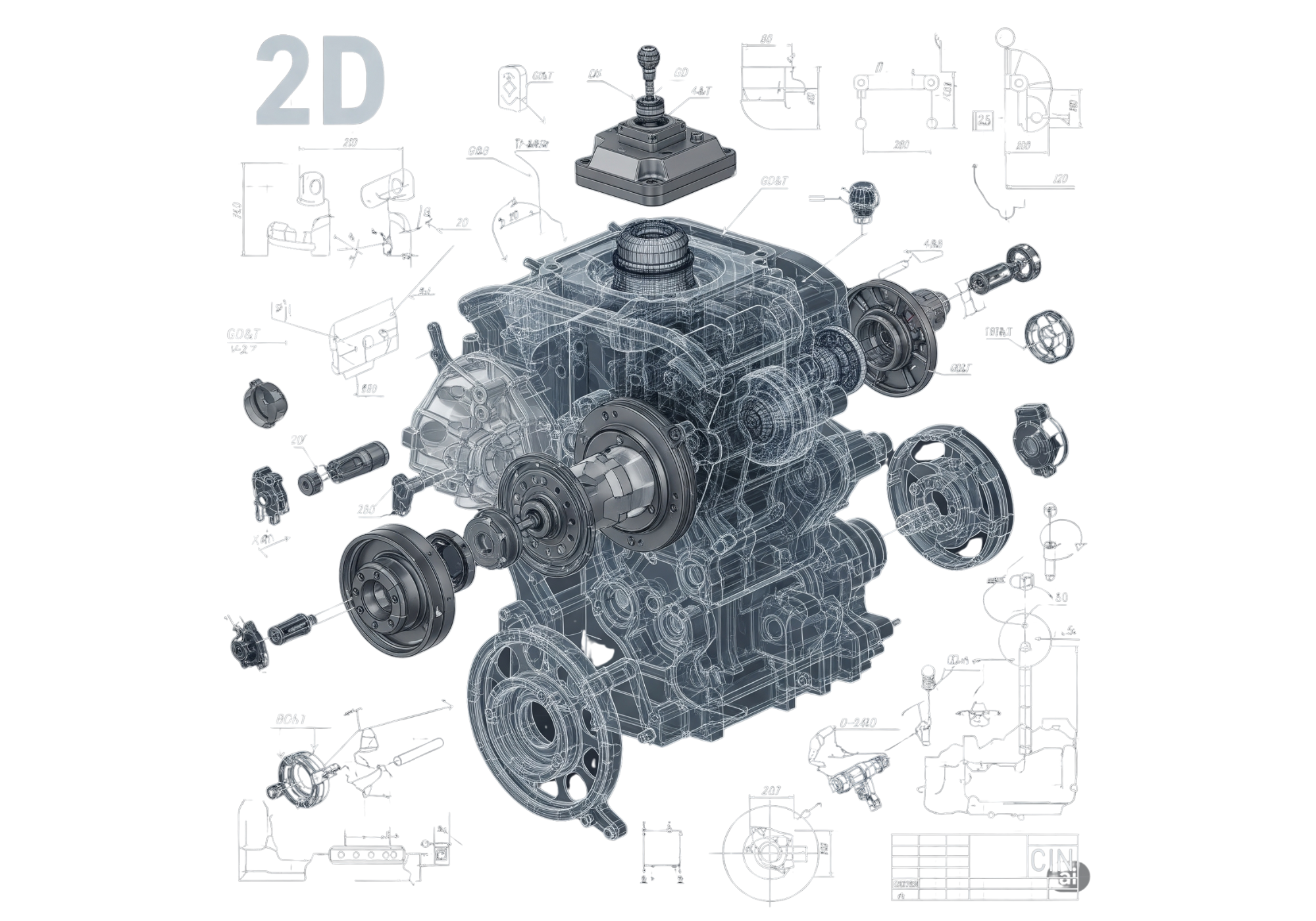

Modern engineering is powered by Computer-Aided Design (CAD). CAD services support product design, drafting, 3D modeling, and virtual prototyping. Contract-based CAD services are ideal for companies looking to...

The synergy of simulation, rendering, prototyping, and manufacturing is shaping the future of product development. Companies that embrace these technologies gain a competitive edge by: From FEA to...